PRODUCTS

SOLID ALUMINUM PANEL

Implementation standard for fluorocarbon spraying performance:

| Test Item | Test Content | Technical Requirement | |

| Geometric Dimensioning | Length, width size | ≤2000mm, the allowable deviation plus or minus 1.0mm | |

| ≥2000mm, the allowable deviation plus or minus 1.5mm | |||

| The diagonal | ≤2000mm, the allowable deviation plus or minus 3.0mm | ||

| >2000mm, the allowable deviation plus or minus 3.0mm | |||

| flatness | Allowable difference ≤1.5mm/m | ||

| Mean dry film thickness | Double coating≥30μm,Triple coating≥40μm | ||

| Fluorocarbon coating | Chromatic aberration | Visual inspection of no obvious color difference or monochromatic paint using a computer color difference meter test AES2NBS |

|

| glossiness | The error of the limit value ≤±5 | ||

| Pencil hardness | ≥±1H | ||

| Dry adhesion | Division method, 100/100, up to level 0 | ||

| Impact resistance(frontal impact) | 50kg.cm(490N.cm), No crack and no paint removal | ||

| Chemical resistance | Hydrochloric acid resistance | Drip for 15 minutes, no air bubbles | |

| Nitric acid resistance |

Color changeΔE≤5NBS | ||

| Resistant mortar | 24 hours without any change | ||

| Resistant detergent | 72 hours no bubbles, no shedding | ||

| Corrosion resistance | Moisture resistance | 4000 hours, up to GB1740 level Ⅱ above | |

| Salt spray resistance | 4000 hours, up to GB1740 level Ⅱ above | ||

| Weather resistance | Fading | After 10years,AE≤5NBS | |

| Efflorescence | After 10 years,GB1766 Level One | ||

| Gloss retention | After 10 years,retention rate≥50% | ||

| Film thickness loss | After 10 years, Film thickness loss rate≤10% | ||

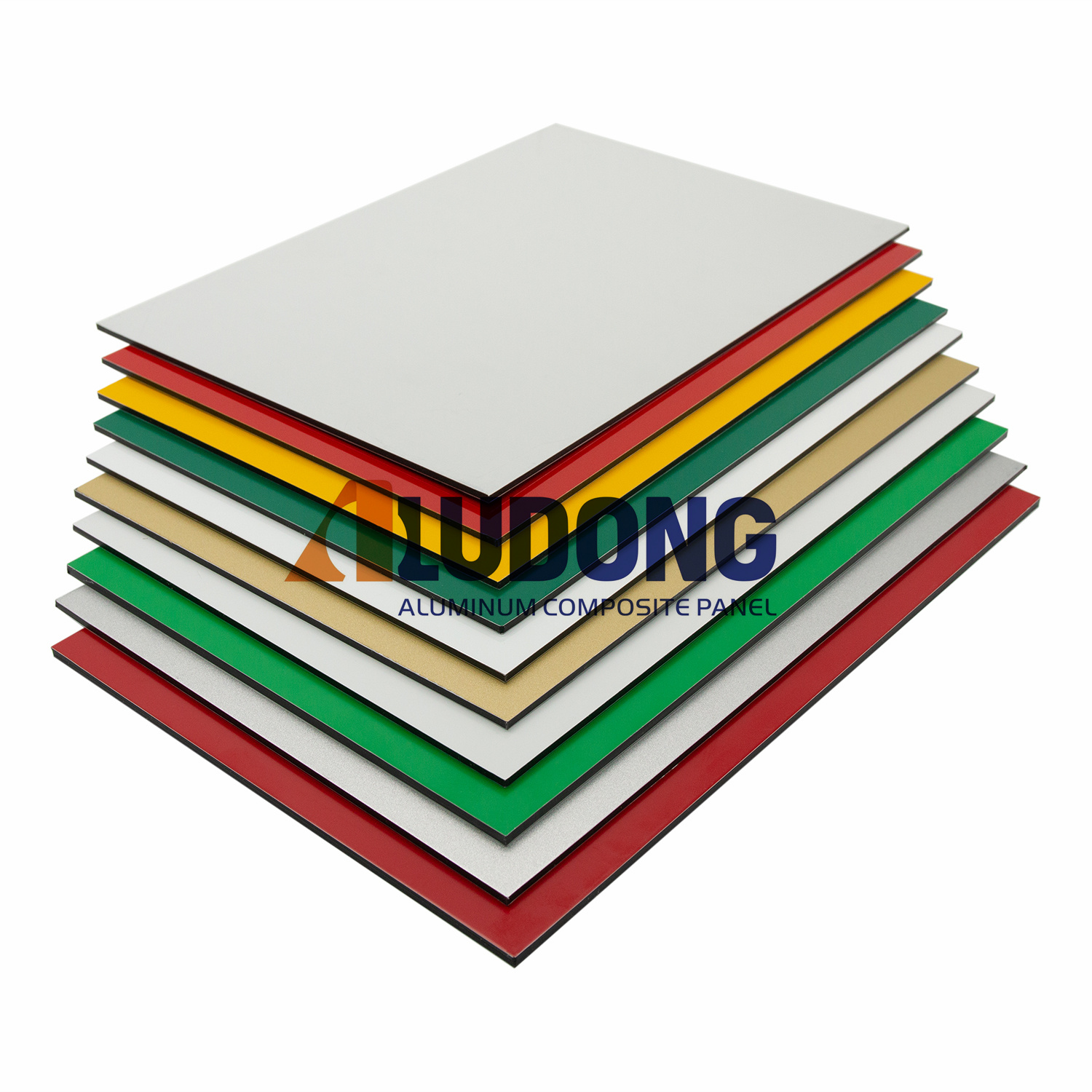

Product details display:

1. Light weight, good rigidity, high strength.

2. Non-Combustible, Excellent fire resistance.

3. Good weather resistance,acid resistance, alkali resistance for exterior.

4. Processed into plane, curved surface and spherical surface, tower shape and other complex shapes.

5. Easy to clean and maintain.

6. Wide color options, good decorative effect.

7. Recyclable, no pollution.

Write your message here and send it to us

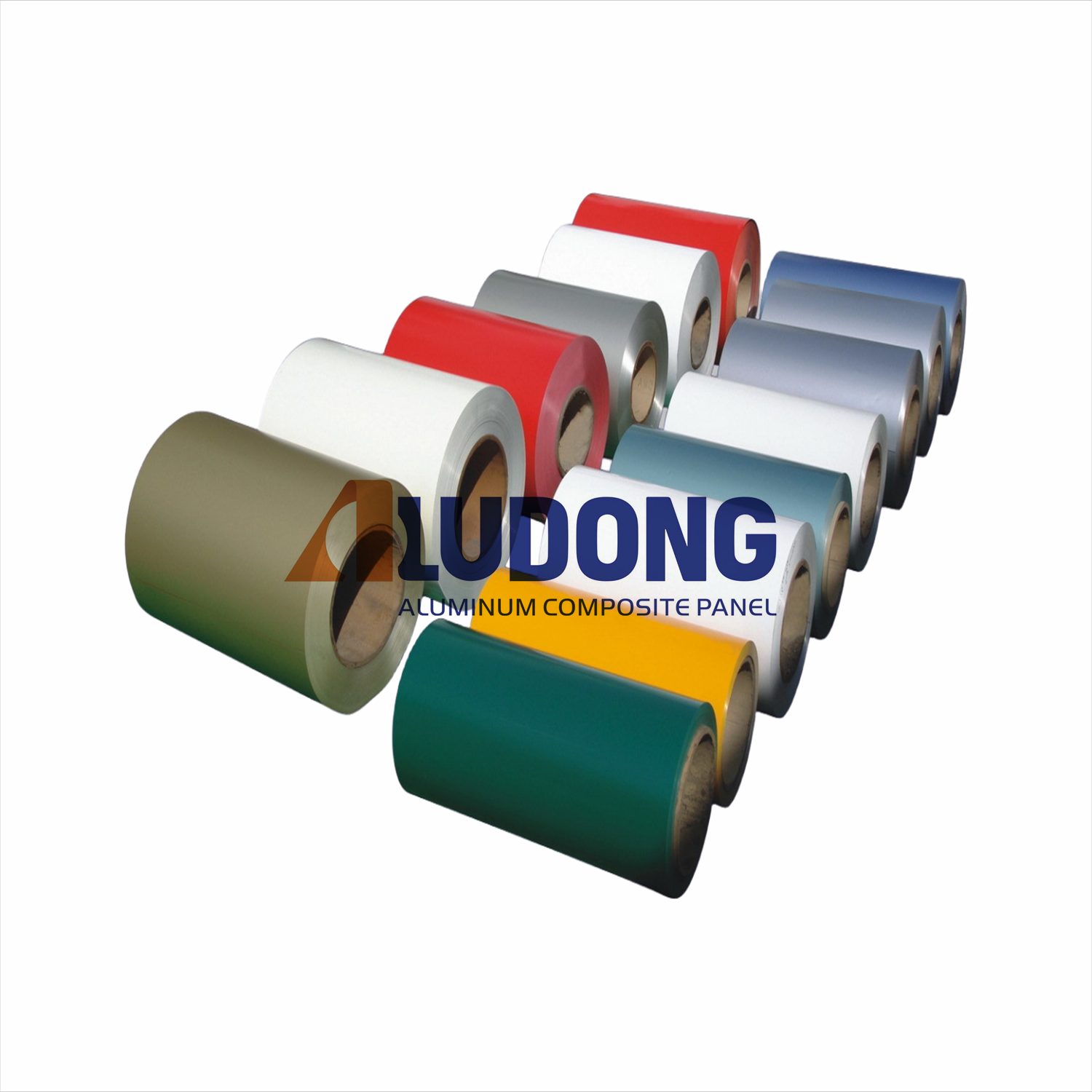

Product recommendation

Our target is to supply stable and high-quality commodities and improve service to you. We sincerely invite worldwide friends to visit our company and hope to establish further cooperation.